KALAMKARI MACHILIPATNAM

The term kalamkari means ‘work done with a pen.’ It is now inseparably attached to the painted and block-printed cotton and silk textiles, produced in the Coromandel Coast (parts of Andhra Pradesh and Tamil Nadu) of India.

At present, two of the most prominent centers of kalamkari production are Srikala Hasti (Chittoor District) and Machilipatnam (Krishna District) in Andhra Pradesh. While in Srikala Hasti, the textiles are painted with pens made from bamboo and cotton, in Machilipatnam, the line drawing done with a pen is transferred onto wooden blocks which are carved and then used to print fabric. In Machilipatnam, the production is carried out in Karkhanas (commercial workshops), where the block makers, washers, and printers work under the same roof.

SO, WHAT KALAMKARI ACTUALLY MEANS?

As with most crafted works, the product (and on occasion the sticker price) regularly misrepresents the tremendous exertion that goes into making them. The fastidious specialty of Kalamkari includes a progression of difficult strides on the textures – to emphasize the magnificence of the fragile examples and the profundity of shadings from regular colors.

When we talk about a product’s worth the people behind the development holds an important role, and when we talk about kalamkari skilled craftsmen are appointed to deal with different undertakings like making the squares, getting ready colors, treating the fabric, washing, printing, and drying. The administrations of somewhere around 8 skilled workers are needed in making the Kalamkari texture of a solitary plan.

Earlier we have talked about the making of squares, so the wooden squares are specially made according to the plan gave. The plans are first drawn on paper and duplicated onto a wooden square. To accomplish a particular plan on the texture would require the formation of no less than 2-3 squares – one for the diagram, the other to fill the shades of the blossoms, as well as leaves and different subtleties. Cutting is an uncommon expertise created with a ton of training and tolerance.

After completing the wooden engraved design it’s time for the colors, the tones utilized for coloring are acquired from normal sources like vegetables, minerals and blossoms, leaves, and bark of various trees. The novel red tone is gotten from an answer of alum and tamarind seed powder. Tamarind seeds are powdered and bubbled until it blends in with water – and afterward, left to cool. This arrangement is separated utilizing a muslin fabric. Alum functions as astringent and helps fix the shading. Like-wise, iron metal is utilized to make dark colors where the mineral is powdered and bubbled to make an answer. The most common way of cooling and sifting is included while making every single vegetable color.

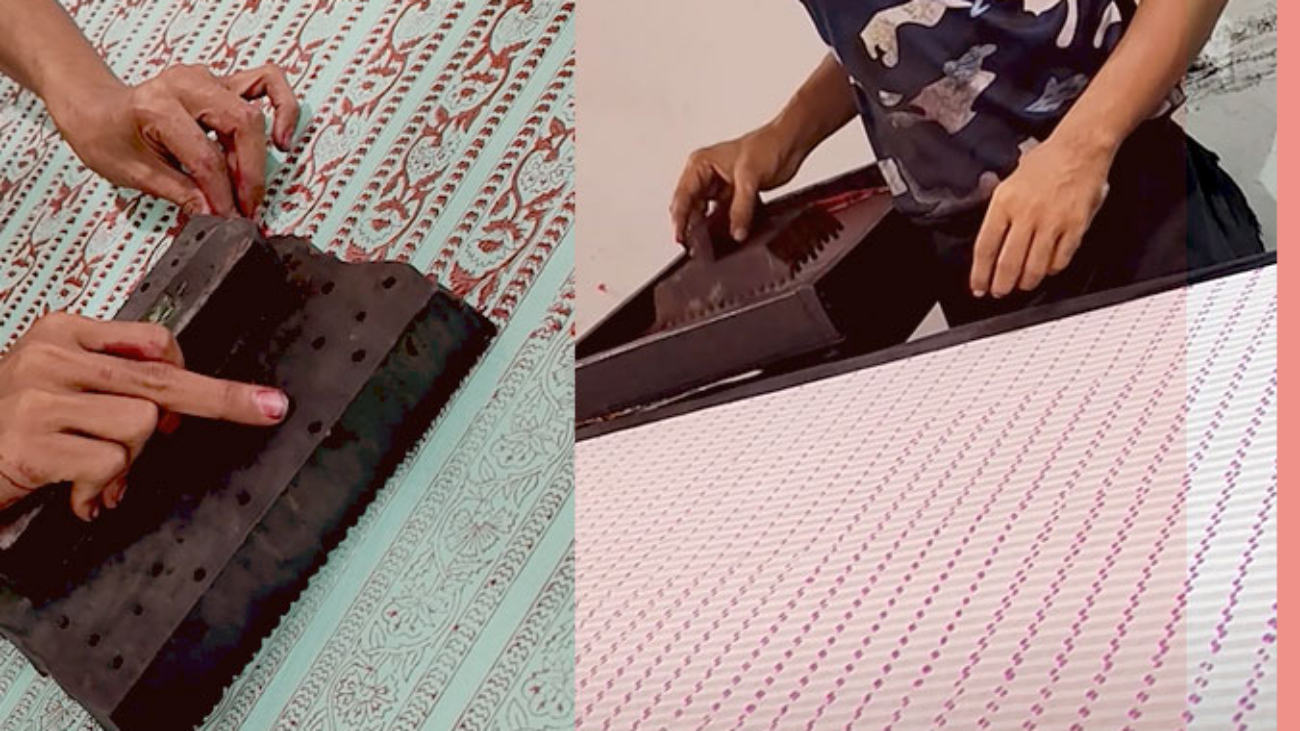

Once we are done with the color preparation, it is directly applied to a texture with the assistance of a wooden square. Contingent upon the plan, continued shading of the texture required. After each round of shading, the textures are spread in daylight for drying. If one somehow managed to watch the craftsmen at work, it is very noteworthy how they get the situation of the squares so exact (with no realistic guides) that the flat and vertical dividing are even.

Finally, when the printing is finished, colors are put cautiously. The texture is subsequently plunged in water to assist tones with getting retained in the texture equally.

WHY IT IS FAMOUS AS KALAMKARI MACHILIPATNAM?

Machilipatnam has demonstrated an optimal area for the art of Kalamkari to flourish because of helpful climate conditions, accessibility of regular assets for colors and mordants, running waters, and a lot of daylight. Since 2013, Machilipatnam Kalamkari has the Geographical Index tag and creation is geologically restricted to the town of Pedana, and adjoining towns of Machilipatnam, Polavaram and Kappaladoddi in the Krishna locale of Andhra Pradesh.

The extraordinary allure of the Kalamkari textures lies in the lavishness of its tones – an aftereffect of fast assimilation of normal colors, and sensitive dreary themes that are a mixture of articulations from Persian and Indian societies.